Views: 221 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

Content Menu

● EVERCROSS BRIDGE: A Leader in Modular Bridge Manufacturing

>> Overview of EVERCROSS BRIDGE

● Other Notable Modular Bailey Bridge Manufacturers in Kenya

>>> Key Features

>> 2. ESC Steel

>>> Key Features

>> 3. iBeehive Steel Structures

>>> Key Features

>> 4. Centunion

>>> Key Features

● The Importance of Modular Bailey Bridges in Kenya

>> Addressing Infrastructure Challenges

>> Environmental Considerations

● Frequently Asked and Questions regarding Modular Bailey Bridge Manufacturers

>> 1. What are the typical lifespan and maintenance requirements for modular Bailey bridges?

>> 3. What are some innovative applications of modular Bailey bridges beyond transportation in Kenya?

>> 4. Are modular Bailey bridges suitable for all types of terrain?

>> 5. How do manufacturers ensure the quality and safety of modular Bailey bridges?

The demand for modular Bailey bridges has surged in recent years, particularly in regions like Kenya where infrastructure development is critical. These bridges are known for their versatility, ease of assembly, and cost-effectiveness, making them ideal for various applications, from temporary crossings to permanent structures. In this article, we will explore the leading manufacturers of modular Bailey bridges in Kenya, highlighting their contributions to the industry and the unique features of their products.

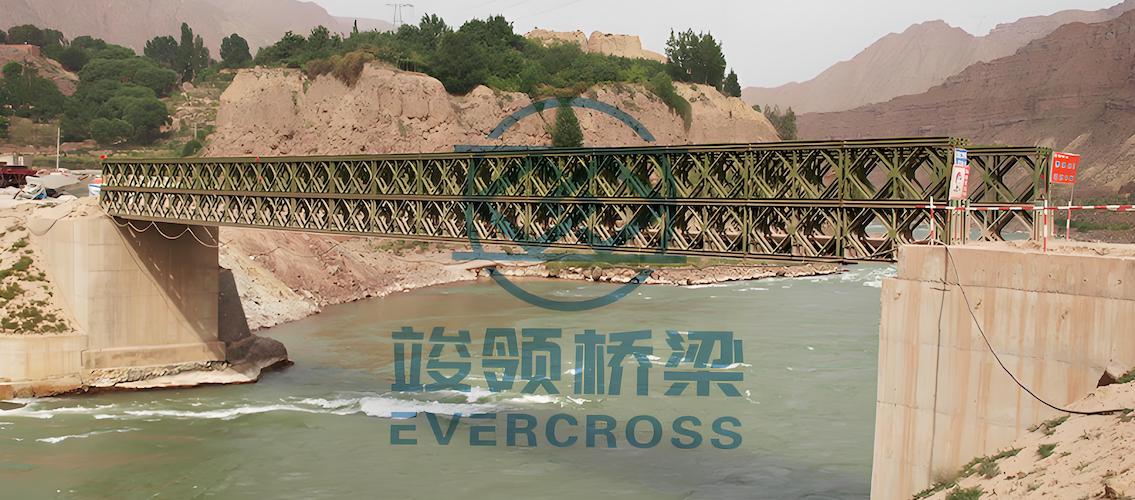

EVERCROSS BRIDGE stands out as one of the top manufacturers of modular Bailey bridges in China, with an impressive annual production capacity exceeding 10,000 tons. The company has established strong partnerships with major state-owned enterprises in China, including China Communications Construction Company, China Railway Group, and China Energy Engineering Group. These collaborations have enabled EVERCROSS BRIDGE to participate in significant projects across various sectors, including railways, highways, and international government procurements. Their reputation for reliability and quality has made them a trusted partner in large-scale infrastructure projects, ensuring that they meet the rigorous standards required for such endeavors.

EVERCROSS BRIDGE specializes in a wide range of modular bridge solutions, including:

Standard Bailey Bridges: These bridges are designed for quick assembly and disassembly, making them suitable for temporary and emergency applications. Their modular design allows for rapid deployment in disaster relief scenarios, where time is of the essence.

Customized Solutions: The company offers tailored designs to meet specific project requirements, ensuring that each bridge can accommodate varying load capacities and environmental conditions. This flexibility allows clients to optimize their infrastructure solutions based on local needs and challenges.

Durability and Safety: EVERCROSS BRIDGE emphasizes the use of high-quality materials and advanced engineering techniques to ensure the longevity and safety of their structures. Their bridges are built to withstand harsh weather conditions and heavy traffic, making them a reliable choice for both urban and rural settings.

Mabey Bridge is a renowned manufacturer with a rich heritage in bridge engineering. They offer a comprehensive range of modular Bailey bridges that are designed for rapid deployment and versatility. Their products are widely used in both temporary and permanent applications, making them a preferred choice for various infrastructure projects in Kenya. The company’s commitment to innovation has led to the development of bridges that not only meet current engineering standards but also incorporate sustainable practices.

Rapid Assembly: Mabey bridges can be assembled quickly on-site, reducing construction time significantly. This efficiency is particularly beneficial in emergency situations where immediate access is required.

Versatile Applications: Their bridges are suitable for military, humanitarian, and civil engineering projects, showcasing their adaptability to different needs. This versatility allows them to serve in diverse environments, from urban centers to remote rural areas.

ESC Steel is another prominent player in the modular bridge market, known for its innovative designs and high-quality manufacturing processes. They provide a variety of modular steel bridges, including Bailey bridges, which are ideal for industrial and commercial use. Their focus on engineering excellence ensures that their products meet the highest standards of safety and performance.

Standardized Components: ESC Steel's bridges are built using standardized parts, facilitating easier assembly and transportation. This standardization not only speeds up the construction process but also reduces costs associated with custom fabrication.

Customizable Designs: They offer flexibility in design, allowing clients to specify dimensions and load capacities according to their project requirements. This customization is crucial for projects that require specific engineering solutions to address unique geographical or logistical challenges.

iBeehive Steel Structures specializes in modular Bailey bridges that are engineered to withstand heavy-duty applications. Their bridges are suitable for both temporary and permanent installations, making them a versatile option for various industries, including construction and mining. The company’s focus on robust design ensures that their bridges can handle the demands of heavy traffic and adverse conditions.

Heavy-Duty Design: iBeehive bridges are built to support substantial loads, ensuring safety and reliability in demanding environments. This capability is particularly important in sectors such as mining, where heavy machinery frequently traverses these structures.

Customization Options: They provide tailored solutions to meet specific project needs, enhancing the functionality of their bridges. This adaptability allows clients to optimize their infrastructure investments based on operational requirements.

Centunion is a key player in the Kenyan market, focusing on delivering high-quality modular steel truss bridges. Their expertise in engineering and design allows them to create bridges that are not only functional but also aesthetically pleasing. This combination of form and function is essential in urban areas where visual impact is a consideration.

Tailored Solutions: Centunion emphasizes customization, ensuring that each bridge meets the unique needs of their clients. This approach allows for the integration of local materials and design elements, enhancing the bridge's compatibility with its surroundings.

Cost-Effective Solutions: Their modular approach enables faster construction times and reduced costs, making them an attractive option for various projects. This efficiency is particularly beneficial for government and NGO projects that operate under tight budgets and timelines.

Kenya faces significant infrastructure challenges, particularly in rural areas where access to reliable transportation is limited. Modular Bailey bridges provide a practical solution to these challenges by offering quick and efficient means of crossing obstacles such as rivers and ravines. Their ability to be deployed rapidly makes them invaluable in emergency situations, such as during floods or natural disasters, where traditional construction methods would be too slow.

The use of modular bridges can lead to substantial economic benefits. They reduce construction time and costs, allowing for faster project completion and improved access to markets and services. This, in turn, can stimulate local economies and enhance the quality of life for communities. Improved infrastructure facilitates trade and mobility, which are essential for economic growth and development.

Modular Bailey bridges are designed with sustainability in mind. Their construction often requires fewer materials and less energy compared to traditional bridge-building methods. Additionally, they can be disassembled and relocated, minimizing their environmental impact. This flexibility is particularly important in sensitive ecological areas where permanent structures could disrupt local ecosystems.

The modular Bailey bridge market in Kenya is thriving, with several manufacturers leading the way in providing innovative and effective solutions for infrastructure development. EVERCROSS BRIDGE, along with other notable companies like Mabey Bridge, ESC Steel, iBeehive Steel Structures, and Centunion, are at the forefront of this industry, contributing to the enhancement of transportation networks across the country. As Kenya continues to develop its infrastructure, the role of these manufacturers will be crucial in ensuring that the nation's bridge-building needs are met efficiently and sustainably. The ongoing collaboration between these companies and local governments will be essential in addressing the challenges of infrastructure development in the years to come.

Modular Bailey bridges typically have a lifespan of 30 to 50 years, depending on the materials used and environmental conditions. Regular maintenance includes inspections for structural integrity, corrosion treatment, and ensuring that connections and joints are secure. Routine maintenance can significantly extend the lifespan of these bridges.

Modular Bailey bridges are generally more cost-effective and quicker to construct than traditional concrete bridges. They can be assembled in a matter of days, while concrete bridges often require weeks or months for curing and setting. Additionally, the lower material costs associated with modular bridges contribute to overall savings in project budgets.

Beyond transportation, modular Bailey bridges can be used for temporary pedestrian walkways, emergency access routes during disasters, and even as platforms for construction sites. They are also utilized in military operations for rapid deployment in conflict zones and can serve as temporary structures for events or festivals.

Yes, modular Bailey bridges are designed to be versatile and can be adapted to various terrains, including hilly, flat, and uneven landscapes. Their modular nature allows for customization in length and width, making them suitable for different environmental conditions and site requirements.

Manufacturers ensure quality and safety through rigorous testing and adherence to engineering standards during the design and production phases. This includes using high-strength materials, conducting load tests, and implementing quality control measures throughout the manufacturing process. Regular inspections and compliance with safety regulations further enhance the reliability of these structures.

What are the structural and construction characteristics of steel cable-stayed bridges?

Are you familiar with the hanging basket technology used in steel temporary bridges?

Do You Know The Structural Classifications of Rigid Frame Bridges?

What Are The Structural Characteristics of Steel Cable-Stayed Bridges and Steel Temporary Bridges?