Views: 212 Author: Site Editor Publish Time: 2026-01-07 Origin: Site

Content Menu

>> Overview

>> Key Projects

>> Overview

>> Overview

>> Overview

>> Overview

>> Contributions to Bridge Construction

● TECMO

>> Overview

● Frequently Asked and Questions regarding Temporary Steel Bridge Manufacturers

>> 1. What are the typical lifespan and maintenance requirements for temporary steel bridges?

>> 2. How do temporary steel bridge manufacturers ensure compliance with Colombian safety standards?

>> 4. What are the advantages of using temporary steel bridges over traditional concrete bridges?

>> 5. How do temporary steel bridges contribute to disaster response and recovery efforts?

Temporary steel bridges are essential for infrastructure development, especially in emergency situations or during construction projects. In Colombia, several manufacturers specialize in producing these vital structures. This article will explore the leading temporary steel bridge manufacturers, highlighting their contributions to the industry and their notable projects.

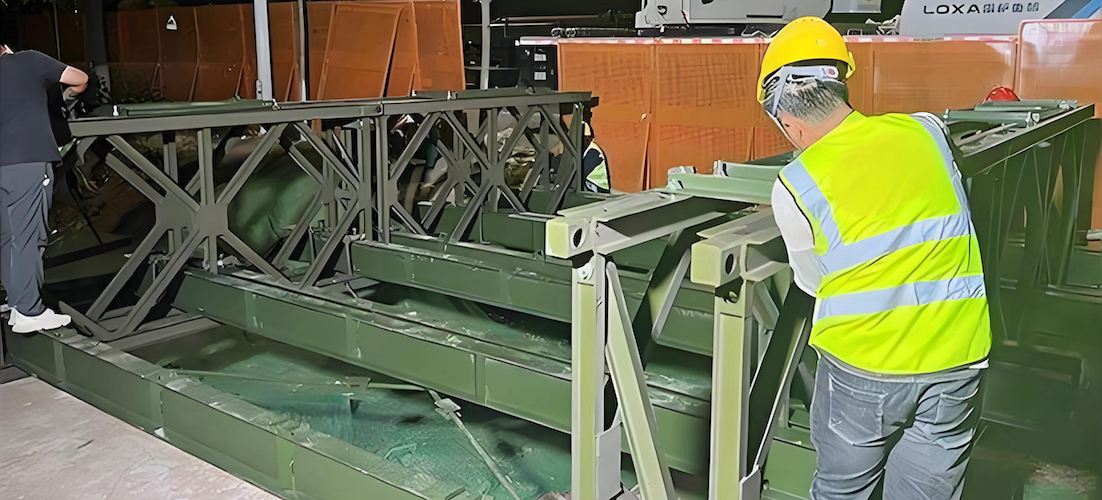

EVERCROSS BRIDGE is a prominent player in the temporary steel bridge manufacturing sector in Colombia. As one of the top three manufacturers in the industry, EVERCROSS BRIDGE boasts an impressive annual production capacity of over 10,000 tons. The company has established strong partnerships with major state-owned enterprises such as China Communications Construction Company, China Railway Group, and China Energy Engineering Group, among others. These collaborations have enabled EVERCROSS BRIDGE to participate in significant projects across various sectors, including railways, highways, and international government procurement. The company’s ability to deliver high-quality products on time has made it a trusted partner for large-scale infrastructure projects.

EVERCROSS BRIDGE has been involved in numerous high-profile projects, showcasing its expertise in designing and manufacturing temporary steel bridges. The company’s bridges are known for their durability, quick installation, and adaptability to different environments. For instance, during natural disasters, their bridges have been deployed rapidly to restore access to affected areas, demonstrating their critical role in emergency response. Their commitment to quality and innovation has made them a preferred choice for both domestic and international clients, further solidifying their reputation in the industry.

Acrow Bridges is a well-known manufacturer of modular and temporary steel bridges, with a strong presence in Colombia. The company specializes in providing solutions for emergency and temporary access needs, making it a vital player in the infrastructure sector. Acrow's bridges are designed for rapid deployment and can be used in various applications, including military, humanitarian, and civil engineering projects. Their focus on modular designs allows for flexibility in construction, enabling quick assembly and disassembly as project needs change.

Acrow Bridges has been instrumental in restoring access to communities affected by natural disasters. Their modular bridge systems can be quickly assembled and disassembled, providing essential connectivity in times of need. For example, after severe flooding in certain regions, Acrow's bridges have been deployed to ensure that residents can access vital services and resources. The company’s focus on innovation and customer service has earned it a solid reputation in the industry, as they continuously seek to improve their products and adapt to the evolving needs of their clients.

Mabey Bridge Limited is another key manufacturer of temporary steel bridges operating in Colombia. With a global footprint, Mabey specializes in modular bridge solutions that are both efficient and cost-effective. Their products are widely used in construction, emergency response, and infrastructure development. The company’s extensive experience in various markets allows them to bring best practices and innovative solutions to their projects in Colombia.

Mabey Bridge Limited is known for its innovative approach to bridge design and construction. The company offers a range of products, including Bailey bridges and other modular structures, which can be tailored to meet specific project requirements. Their bridges are designed to withstand harsh environmental conditions, ensuring longevity and reliability. Additionally, Mabey’s commitment to sustainability and quality ensures that their bridges are not only functional but also environmentally friendly, aligning with global standards for sustainable construction practices.

G&J Empresas de Acero is a Colombian company that specializes in the production of steel structures, including temporary bridges. With decades of experience in the industry, G&J has established itself as a reliable provider of high-quality steel solutions for various construction needs. Their expertise in steel fabrication allows them to create customized solutions that meet the specific demands of each project.

The company has been involved in numerous infrastructure projects across Colombia, providing temporary bridge solutions that enhance connectivity and safety. G&J’s bridges are often used in challenging terrains where traditional construction methods may be impractical. Their dedication to community development and infrastructure improvement has made them a respected name in the industry, as they strive to contribute positively to the regions they serve.

CSS Constructores S.A. is a major player in the Colombian construction industry, focusing on large-scale infrastructure projects, including bridge construction. The company is known for its commitment to quality and sustainability, employing advanced technology and skilled resources to deliver innovative engineering solutions. Their approach combines traditional construction methods with modern technology, ensuring efficiency and effectiveness in their projects.

CSS Constructores has successfully completed various bridge projects, utilizing temporary steel bridges to facilitate construction and improve access in challenging environments. Their bridges are designed to support heavy loads and withstand adverse weather conditions, making them suitable for both urban and rural applications. The company’s focus on safety and quality assurance has earned them numerous accolades in the construction sector, further establishing their reputation as a leader in bridge construction.

TECMO is a Colombian company with over six decades of experience in manufacturing and installing metallic structures, including temporary steel bridges. The company is recognized for its commitment to quality and customer satisfaction, which has been acknowledged by various industry awards. TECMO’s extensive experience allows them to tackle complex projects with confidence, ensuring that they meet the diverse needs of their clients.

TECMO has been involved in several significant projects, providing temporary bridge solutions that enhance infrastructure and connectivity. Their expertise in steel fabrication and installation ensures that their bridges are durable and reliable, meeting the needs of diverse clients. The company’s ability to adapt to different project requirements and environments has made them a preferred choice for many infrastructure developments across Colombia.

The temporary steel bridge manufacturing industry in Colombia is supported by several key players, each contributing to the development of essential infrastructure. Companies like EVERCROSS BRIDGE, Acrow Bridges, Mabey Bridge Limited, G&J Empresas de Acero, CSS Constructores S.A., and TECMO are at the forefront of this sector, providing innovative solutions that enhance connectivity and support community development. As the demand for temporary bridges continues to grow, these manufacturers will play a crucial role in shaping the future of infrastructure in Colombia. Their commitment to quality, innovation, and sustainability will ensure that they remain leaders in the industry, capable of meeting the challenges of tomorrow.

Temporary steel bridges typically have a lifespan ranging from 5 to 20 years, depending on the materials used and environmental conditions. Regular maintenance is essential to ensure their structural integrity, which includes inspections for corrosion, structural damage, and wear. Maintenance activities may involve repainting, replacing damaged components, and ensuring that the bridge remains free of debris.

Manufacturers comply with Colombian safety standards by adhering to national regulations and international best practices in bridge design and construction. This includes conducting thorough engineering assessments, using certified materials, and implementing quality control measures throughout the manufacturing process. Additionally, many manufacturers engage in regular training for their staff to stay updated on safety protocols and standards.

Innovations in temporary steel bridge technology include the development of modular designs that allow for quick assembly and disassembly, lightweight materials that reduce transportation costs, and advanced engineering techniques that enhance load-bearing capacity. Some manufacturers are also exploring the use of smart technologies, such as sensors for real-time monitoring of structural health, which can provide data on stress and wear over time.

Temporary steel bridges offer several advantages over traditional concrete bridges, including faster installation times, lower costs, and greater flexibility in design. They can be easily transported and assembled in remote or difficult-to-access locations, making them ideal for emergency situations. Additionally, steel bridges are often lighter than concrete, which can reduce the need for extensive foundation work.

Temporary steel bridges play a crucial role in disaster response by providing immediate access to affected areas, allowing for the transportation of emergency supplies, personnel, and equipment. Their rapid deployment capabilities enable communities to restore connectivity quickly, which is vital for recovery efforts. By facilitating access to essential services, these bridges help mitigate the impact of disasters on local populations.