Views: 221 Author: Site Editor Publish Time: 2026-01-21 Origin: Site

Content Menu

>> Key Features of Bailey Panels

● Structural Composition of Bailey Panels

● Applications of Bailey Panels

● Recent Innovations in Bailey Panel Design

>> Enhanced Load-Bearing Capacity

>> Modular Design Improvements

>> Integration of Smart Technology

● Case Studies: Successful Implementations of Bailey Panels

● Frequently Asked and Questions regarding Bailey Panels

>> 1. What are the typical dimensions and weight of a standard Bailey panel?

>> 2. How do environmental factors like corrosion affect the lifespan of Bailey bridges?

>> 5. What safety measures are in place to ensure the structural integrity of Bailey bridges?

Bailey panels, known for their simple structure, easy transportation, and quick assembly, are essential components in modern bridge construction. These panels are designed to support significant loads and adapt to various environmental conditions, making them a preferred choice in infrastructure projects worldwide. This article delves into the structural composition of Bailey panels, their applications, and the latest advancements in their design and use. Understanding the intricacies of Bailey panels not only highlights their importance in engineering but also showcases their versatility in addressing diverse construction challenges.

Bailey panels are modular steel bridge components that can be quickly assembled to form a complete bridge structure. Originally developed during World War II, these panels have evolved significantly, particularly in China, where they are adapted to meet local conditions and requirements. The “321” steel bridge, a product of this evolution, combines the traditional Bailey design with modern engineering techniques to enhance stability, fatigue life, and reliability. This adaptability has made Bailey panels a staple in both temporary and permanent bridge solutions, reflecting their enduring relevance in contemporary civil engineering.

Simplicity: The design of Bailey panels allows for straightforward assembly and disassembly, which is crucial in emergency situations where time is of the essence. This simplicity reduces the need for specialized labor, making it accessible for various construction teams.

Transportability: Their modular nature makes them easy to transport to various construction sites, often in standard shipping containers. This feature is particularly beneficial for remote or disaster-stricken areas where traditional construction materials may be difficult to deliver.

Load Capacity: Bailey panels can support heavy loads, making them suitable for both military and civilian applications. Their engineering allows for the construction of bridges that can accommodate not just pedestrian traffic but also heavy vehicles, ensuring safety and functionality.

Versatility: They can be used in a variety of settings, from temporary military bridges to permanent infrastructure. This versatility extends to their design, allowing for customization based on specific project needs, such as span length and load requirements.

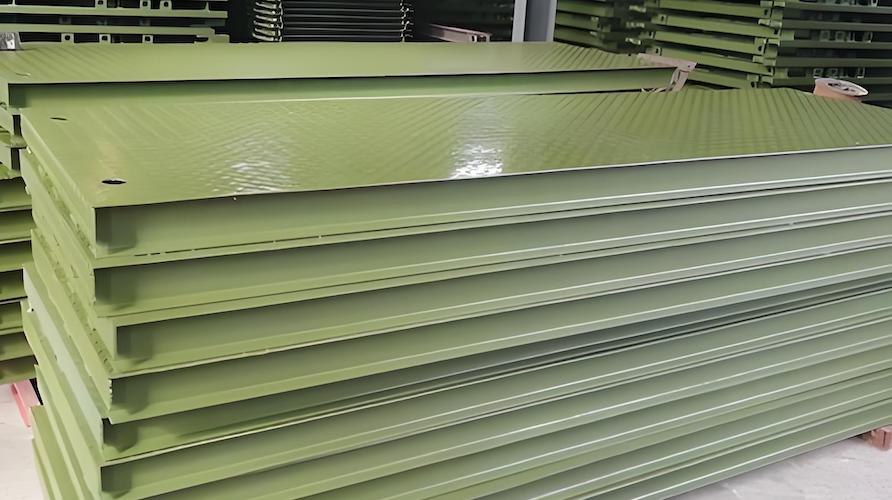

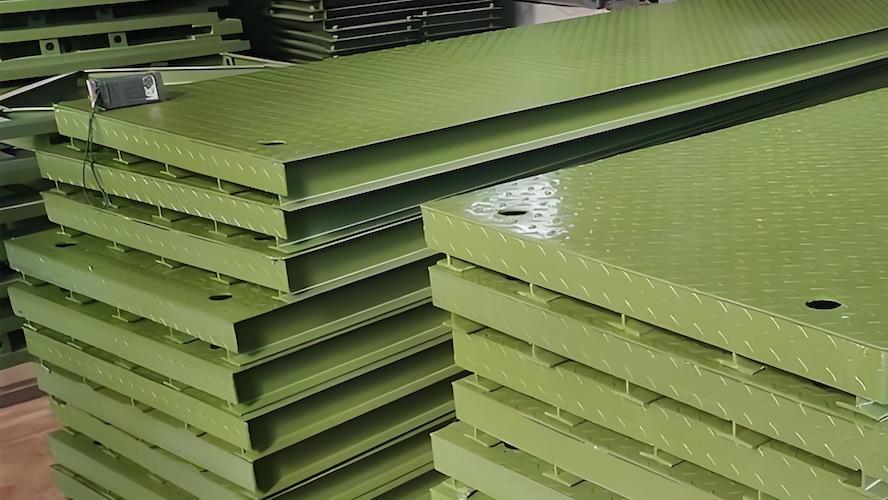

Modern Bailey panels are primarily constructed from high-strength steel, which provides durability and resilience. The vertical members of the panels are typically made from 8 I-beams, which are designed to withstand significant stress and strain. The use of high-quality materials ensures that the panels can endure harsh environmental conditions and heavy traffic loads. Additionally, advancements in steel manufacturing have led to the development of corrosion-resistant coatings, further extending the lifespan of these panels in various climates.

The design of Bailey panels includes several critical components:

Vertical Members: Made from I-beams, these provide the primary support structure. The choice of I-beam design maximizes strength while minimizing weight, allowing for easier handling and installation.

Horizontal Members: These connect the vertical members and distribute loads evenly across the panel. Their design is crucial for maintaining the structural integrity of the bridge under dynamic loads, such as those caused by moving vehicles.

Rectangular Holes: Incorporated into the vertical members, these holes are used for securing the panels together, enhancing stability and ease of assembly. This feature allows for quick connections and disconnections, facilitating rapid deployment in emergency scenarios.

The assembly of Bailey panels is a straightforward process that can be completed quickly, often within a few hours. The panels are connected using bolts and pins, allowing for easy disassembly and reconfiguration as needed. This flexibility is particularly beneficial in emergency situations where rapid deployment is essential. The assembly process can be performed with minimal equipment, making it feasible for teams to set up bridges in challenging environments without the need for heavy machinery.

Bailey panels are widely used in various sectors, including:

Military Engineering: Their rapid deployment capabilities make them ideal for military applications, providing temporary bridges in conflict zones. The ability to quickly establish crossing points can be critical for logistics and troop movements.

Civil Infrastructure: Many countries utilize Bailey panels for constructing roads, railways, and pedestrian bridges due to their cost-effectiveness and efficiency. Their modular nature allows for easy upgrades and repairs, ensuring long-term usability.

Disaster Relief: In the aftermath of natural disasters, Bailey panels can be quickly assembled to restore access to remote areas. This capability is vital for humanitarian efforts, allowing for the swift delivery of aid and resources to affected populations.

Recent advancements in material science have led to the development of stronger steel alloys, which increase the load-bearing capacity of Bailey panels. This enhancement allows for the construction of longer spans and heavier traffic loads without compromising safety. Engineers are now able to design bridges that can accommodate modern transportation demands, including larger vehicles and increased traffic volumes.

The latest designs incorporate modular components that can be easily replaced or upgraded. This modularity not only simplifies maintenance but also allows for the customization of bridges to meet specific project requirements. For instance, panels can be designed with varying widths and lengths to suit different applications, from narrow pedestrian walkways to wide vehicular bridges.

Innovations in smart technology are being integrated into Bailey panel designs. Sensors can be embedded within the panels to monitor structural integrity and performance in real-time, providing valuable data for maintenance and safety assessments. This proactive approach to bridge management helps identify potential issues before they become critical, enhancing overall safety and reducing long-term maintenance costs.

In 2020, following a devastating earthquake in Sichuan, Bailey panels were deployed to quickly restore access to remote areas. The rapid assembly of these bridges allowed for the swift delivery of aid and resources, demonstrating the effectiveness of Bailey panels in emergency situations. This case highlights the importance of having pre-fabricated solutions ready for deployment in disaster-prone regions.

Bailey panels represent a significant advancement in bridge construction technology, combining simplicity, strength, and adaptability. As the demand for efficient infrastructure solutions continues to grow, the role of Bailey panels in both military and civilian applications will remain crucial. Their ongoing evolution, driven by technological advancements and innovative design, ensures that they will continue to meet the challenges of modern engineering.

A standard Bailey panel typically measures 3 meters in width and 1.5 meters in height. The weight of a single panel can vary depending on the specific design and materials used, but it generally ranges from 200 to 300 kilograms. These dimensions allow for easy handling and transportation, making them suitable for rapid assembly in various construction scenarios.

Environmental factors such as moisture, salt, and temperature fluctuations can significantly impact the lifespan of Bailey bridges. Corrosion is a primary concern, especially in coastal areas or regions with high humidity. To mitigate this, modern Bailey panels are often treated with corrosion-resistant coatings or made from high-strength, weather-resistant steel alloys. Regular maintenance and inspections are also essential to identify and address any signs of corrosion early.

The cost of using Bailey panels is generally lower than traditional bridge construction methods due to their modular design and quick assembly time. This reduces labor costs and the need for heavy machinery. Additionally, Bailey panels can be reused and relocated, providing long-term savings. However, the initial investment may vary based on the specific project requirements, materials, and local labor costs.

While Bailey panels are often associated with temporary structures, they can also be used for permanent applications. With proper design, engineering, and maintenance, Bailey bridges can serve as long-lasting solutions for various infrastructure needs. Many countries have successfully implemented Bailey panels in permanent installations, particularly in remote or challenging environments where traditional construction may be impractical.

Safety measures for Bailey bridges include rigorous design standards, regular inspections, and load testing. Engineers ensure that the panels are constructed from high-quality materials that meet safety regulations. Additionally, embedded sensors can monitor the structural health of the bridge in real-time, providing data on stress, strain, and potential issues. Maintenance protocols are also established to address any wear and tear, ensuring the bridge remains safe for use.

Construction Methods for Bailey Frame Support in Concrete Pouring of Lift Platforms

Comprehensive Guide to Bailey Bridges: Characteristics, Assembly, and Best Practices

Understanding Steel Temporary Bridges: Features, Benefits, and Applications

Prefabricated Steel Bridges: The Ideal Temporary Solutions for Modern Infrastructure

Application of Steel Bridges in Municipal Pipeline Protection