Views: 221 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

Content Menu

● Understanding Bailey Bridges

● 1. Cantilever Launching Method

>> This process includes the following key steps

● 4. Incremental Launching Method

● Enhancing Installation Efficiency

● Frequently Asked and Questions regarding Installation Methods for Bailey Bridges

>> 2: What are the safety precautions necessary during the cantilever launching of a Bailey bridge?

>> 4: How does weather impact the installation of Bailey bridges using the cantilever launching method?

Bailey bridges, renowned for their modular design and rapid assembly capabilities, are essential in various construction projects, including military, emergency, and civilian applications. This article delves into the most common installation methods for Bailey bridges, ensuring that engineers and contractors can select the most effective approach tailored to their specific project requirements. With a production capacity exceeding 10,000 tons annually, EVERCROSS BRIDGE stands as a leading manufacturer in this sector, collaborating with major enterprises like China Communications Construction Company and China Railway Group to deliver high-quality bridge solutions.

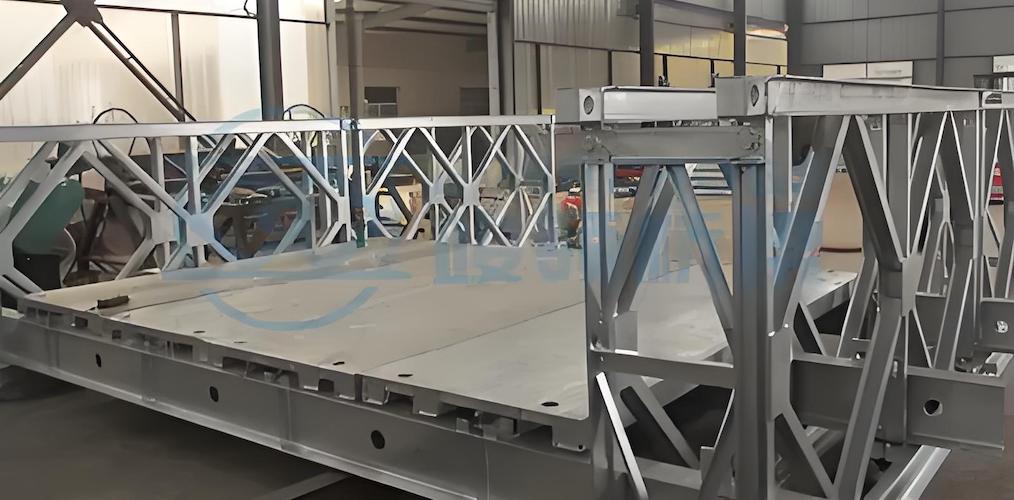

Bailey bridges are prefabricated, portable structures made from steel components, designed for quick assembly and disassembly. Their modular nature allows for easy transportation and installation, making them ideal for temporary or emergency use. The versatility of Bailey bridges enables them to be deployed in various scenarios, from providing immediate access in disaster-stricken areas to serving as reliable infrastructure in military operations. The ability to adapt to different environments and requirements is a key factor in their widespread adoption.

The cantilever erection method is the most commonly used technique for installing Bailey bridges, especially in areas where heavy lifting equipment is inaccessible. This method is favored for its simplicity and efficiency, suitable for various terrains and conditions, and requires only minimal training for workers to undertake the bridge erection task.

The cantilever launching method directly involves installing rocker and roller supports on both banks of the river. Most of the bridge components are pre-assembled on the rollers on the launching bank, and then the bridge is smoothly and slowly pushed across using manpower or mechanical traction until it reaches the rocker supports on the opposite bank.

●Preparation: First, temporary supports are set up on both sides of the riverbank or gap at the bridge installation location. This initial setup is crucial for ensuring stability during the installation process.

●Assembly: The various parts of the bridge are pre-assembled on one side of the gap. This may include connecting beams and panels to form larger sections, significantly reducing the time required for actual installation.

●Erection: The assembled bridge sections are pushed across the gap using hydraulic jacks. This method allows for gradual and controlled movement, minimizing the risk of structural damage during the transition.

●Final Adjustment: Once the bridge is in place, measuring tools are used to ensure it is level and stable. This step is critical for the safety and functionality of the bridge, as any misalignment could lead to structural problems.

◆This erection method primarily requires careful calculation of various parameters, including the structural analysis of the Bailey bridge span before assembly, the number of nose sections for various combinations and spans, the launching weight and nose section end deflection. The nose section length must conform to the following rule: Number of nose sections = Number of bridge sections / 2 + 1.

◆For example, a double-row single-layer 24m bridge would have a nose section of: 8/2 + 1 = 5 sections. For bridges with an odd number of sections, the number of sections needs to be divided by 2, rounded down to the nearest integer, and then 1 is added.

◆The calculation of the launching capacity of the shore-side roller support is as follows: Assuming a reinforced double-row single-layer bridge with a span of 33m, the bridge nose is a single-row single-layer truss structure with 7 sections, and the roller is placed 0.75m in front of the seating plate (on the river side).

◆The weight of each bridge section is 35.7 kN, and the weight of each section of the single-row single-layer nose truss is 9.0 kN. Therefore, the launching weight of the bridge is: 11 × 35.7 + 7 × 9.0 = 455.7 kN.

◆When erecting a reinforced double-row bridge, four rollers are used on the launching shore. The load bearing capacity of each roller is: 455.7 / 4 = 113.9 kN, which is less than the designed capacity of 250 kN, so the rollers are safe.

The cantilever erection method is particularly advantageous in environments where space is limited or the terrain is complex, making traditional cranes impractical. This method requires simple equipment and allows for quick worker training, making it the preferred choice for many contractors.

The float-in method is ideal for installations over water bodies, leveraging the buoyancy of water to facilitate the positioning of the bridge. This technique involves:

●Floating the Bridge: Assemble the bridge sections on a barge or floating platform, allowing for easy transportation to the installation site.

●Positioning: Use tugboats to maneuver the floating bridge into position, ensuring it aligns correctly with the pre-installed supports.

●Securing: Once the bridge is aligned, lower it onto the supports, ensuring all connections are secure and stable.

This method is particularly useful in scenarios where the installation site is inaccessible by land vehicles, providing a practical solution for remote or challenging locations.

The full span lifting method is suitable for shorter spans and involves lifting the entire bridge section into place using cranes. The steps include:

●Cranes Setup: Position cranes on both sides of the installation site, ensuring they are capable of handling the weight of the bridge.

●Lifting: Carefully lift the bridge section and place it onto the supports, requiring precise coordination among the crane operators.

●Securing: After placement, ensure all connections are tightened and secure, conducting thorough inspections to confirm the bridge's integrity.

This method is effective for quick installations but requires careful planning and coordination to avoid accidents.

The incremental launching method is effective for longer spans and involves launching the bridge in increments. The process includes:

●Initial Setup: Assemble the first section of the bridge on one side, ensuring it is stable and secure.

●Incremental Launching: Gradually extend the bridge by adding sections and pushing them forward using hydraulic jacks. This method allows for continuous progress and can be adjusted based on site conditions.

●Final Placement: Once the entire bridge is launched, secure it in place, ensuring all components are properly aligned and connected.

This method is particularly useful for projects requiring precise control over the installation process, allowing for adjustments as needed.

To improve the efficiency of Bailey bridge installations, consider the following best practices:

●Pre-assembly: Assemble as many components as possible before the actual installation to save time and reduce on-site labor.

●Training: Provide thorough training for workers on the specific installation methods to ensure safety and efficiency. This can include hands-on workshops and simulations to prepare them for real-world scenarios.

●Use of Technology: Implement modern technology, such as drones for site surveys and 3D modeling for planning, to enhance accuracy and streamline the installation process.

Bailey bridges offer versatile solutions for various construction needs, from emergency response to military applications. By understanding different installation methods, particularly the cantilever method, engineers can ensure the successful and efficient deployment of steel bridges, adapting the actual construction to the specific product and site conditions. This not only simplifies the installation process but also enhances safety and reliability.

The cantilever launching method is typically used for spans ranging from 10 to 60 meters (approximately 33 to 197 feet). However, with proper engineering and design considerations, it can accommodate longer spans depending on the specific bridge configuration and site conditions.

Safety precautions during the cantilever launching method include:

●Conducting a thorough site assessment to identify potential hazards.

●Ensuring all workers are trained in the specific installation procedures and safety protocols.

●Using appropriate personal protective equipment (PPE) such as helmets, gloves, and safety harnesses.

●Regularly inspecting equipment, including hydraulic jacks and temporary supports, to ensure they are in good working condition.

●Establishing clear communication among team members to coordinate movements and actions during the installation process.

The cantilever launching method can be more cost-effective than other methods, such as full span lifting, especially in sites where heavy cranes cannot operate. It reduces the need for expensive lifting equipment and minimizes labor costs due to its straightforward assembly process. However, the overall cost will depend on factors such as site conditions, bridge design, and the availability of materials.

Weather conditions can significantly impact the installation process. High winds, heavy rain, or extreme temperatures can affect the stability of the bridge sections during launching. It is essential to monitor weather forecasts and plan installations during favorable conditions. If adverse weather is anticipated, it may be necessary to delay the installation to ensure safety and structural integrity.

Yes, Bailey bridges are designed for reuse. After disassembly, the components can be inspected for wear and damage before being reinstalled at a new location. Key considerations for reinstallation include ensuring that the new site meets the structural requirements for the bridge, conducting a thorough site assessment, and following the original installation guidelines to maintain safety and performance standards.