Views: 245 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

Content Menu

● Overview of Steel Box Bridges

>> Key Projects and Collaborations

>> Innovations and Capabilities

>> Contributions to Bridge Manufacturing

>> Specialization in Steel Bridges

>> Overview

>> Bridge Construction Expertise

● 6. Tensar International Corporation

>> Role in Steel Bridge Manufacturing

>> Innovations in Bridge Engineering

>> Contributions to Steel Box Bridges

>> Role in Bridge Manufacturing

>> Specialization in Steel Box Bridges

● Frequently Asked and Questions regarding Steel Box Bridge Manufacturers

>> 1. What are the typical dimensions and weight limitations for steel box girder bridges?

>> 2. How do steel box girder bridges compare to concrete bridges in terms of cost and lifespan?

>> 3. What are the latest advancements in steel box girder bridge design and construction techniques?

>> 4. What maintenance practices are essential for steel box bridges?

>> 5. What factors influence the choice between steel and concrete for bridge construction?

Steel box bridges are a vital component of modern infrastructure, providing strength and durability for various transportation needs. In the United States, several manufacturers excel in producing these essential structures. This article will explore the top steel box bridge manufacturers, highlighting their contributions to the industry and showcasing their capabilities. Among these, EVERCROSS BRIDGE stands out as a leading player, known for its high-quality production and extensive collaboration with major enterprises.

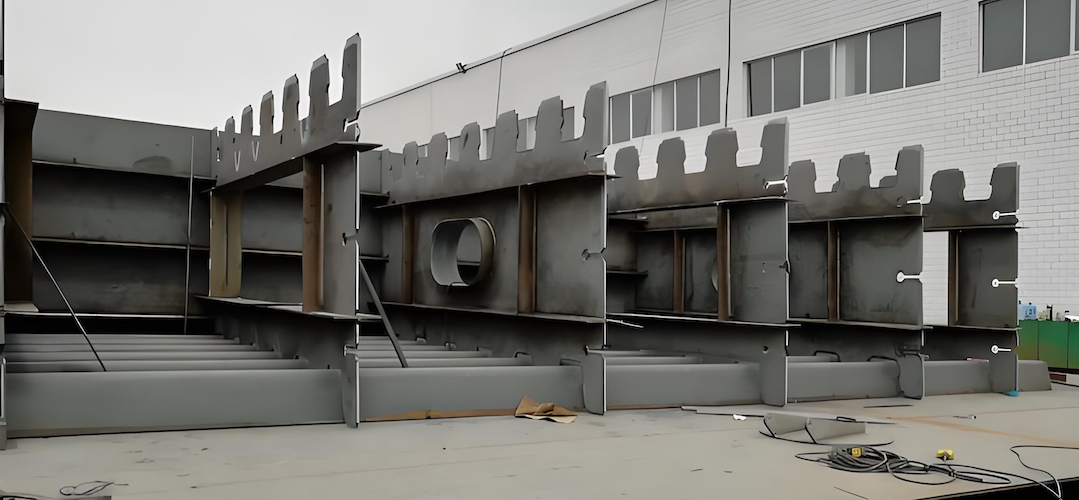

Steel box bridges are characterized by their box-shaped girders, which provide excellent structural integrity and load-bearing capacity. These bridges are commonly used in highway and railway applications due to their ability to span long distances without the need for intermediate supports. The manufacturing process involves advanced techniques and materials to ensure safety, longevity, and efficiency. The design of steel box bridges allows for a lightweight yet robust structure, making them ideal for various environments, including urban settings and remote areas. Their versatility in design also enables engineers to adapt them to specific project requirements, enhancing their functionality and aesthetic appeal.

Founded in China, EVERCROSS BRIDGE has rapidly established itself as one of the top manufacturers of steel bridges globally. With an annual production capacity exceeding 10,000 tons, the company specializes in various types of steel bridges, including box girders, truss bridges, and modular structures. Their commitment to quality and innovation has led to successful collaborations with major state-owned enterprises in China, such as China Communications Construction Company and China Railway Group. This extensive experience in large-scale projects has equipped EVERCROSS with the expertise to handle complex engineering challenges, ensuring that their bridges meet international standards for safety and performance.

EVERCROSS BRIDGE has participated in numerous significant projects, including railway and highway constructions, as well as international government procurement initiatives. Their partnerships with leading companies demonstrate their capability to handle large-scale projects efficiently. For instance, their collaboration with China National Offshore Oil Corporation on offshore bridge projects showcases their ability to adapt to diverse environments and requirements. The company’s focus on sustainable practices and innovative solutions has also positioned them as a forward-thinking leader in the industry, paving the way for future advancements in bridge technology.

American Bridge Company is one of the oldest and most respected bridge construction firms in the United States. Established in 1900, the company has a rich history of engineering excellence and innovation. They are known for their involvement in iconic projects, including the Golden Gate Bridge and the George Washington Bridge. This legacy of landmark constructions not only highlights their engineering capabilities but also reflects their commitment to pushing the boundaries of bridge design and construction techniques.

American Bridge Company specializes in various bridge types, including steel box girders. Their expertise in complex bridge designs and construction techniques has made them a leader in the industry. They focus on sustainability and safety, ensuring that their projects meet the highest standards. The company invests heavily in research and development, exploring new materials and construction methods that enhance the durability and efficiency of their bridges. Their innovative approach has led to the development of advanced monitoring systems that ensure the long-term integrity of their structures, providing peace of mind to stakeholders and users alike.

Steel Dynamics, Inc. is a major player in the steel industry, known for its diverse range of products, including steel for bridge construction. Founded in 1993, the company has quickly grown to become one of the largest steel producers in the United States. Their rapid growth can be attributed to their commitment to quality and customer service, which has earned them a loyal client base across various sectors.

Steel Dynamics produces high-quality steel that is used in various bridge applications, including box girders. Their commitment to innovation and efficiency in production processes has positioned them as a key supplier for many bridge projects across the country. The company employs state-of-the-art technology in their manufacturing processes, ensuring that their steel products meet stringent quality standards. Additionally, their focus on sustainability is evident in their use of recycled materials and energy-efficient production methods, which contribute to reducing the environmental impact of their operations.

Cleveland Bridge has a long-standing reputation for quality and reliability in bridge construction. With a history dating back to the 19th century, the company has been involved in numerous landmark projects worldwide. Their extensive experience in the field has allowed them to develop a deep understanding of the challenges and requirements associated with bridge construction, making them a trusted partner for many infrastructure projects.

Cleveland Bridge specializes in the design and manufacture of steel bridges, including box girders. Their engineering expertise and commitment to quality have made them a preferred choice for many infrastructure projects. The company’s portfolio includes a wide range of bridge types, from pedestrian walkways to major highway overpasses, showcasing their versatility and capability to meet diverse project needs. Their focus on innovation is reflected in their use of advanced design software and construction techniques, which enhance the efficiency and safety of their projects.

Kiewit Corporation is one of the largest construction and engineering organizations in North America. Founded in 1884, Kiewit has a diverse portfolio that includes transportation, water resources, and power projects. Their extensive experience in various sectors allows them to leverage best practices and innovative solutions across their projects, ensuring high-quality outcomes.

Kiewit is known for its extensive experience in bridge construction, including steel box bridges. Their ability to manage large-scale projects and deliver high-quality results has earned them a strong reputation in the industry. The company employs a collaborative approach, working closely with clients and stakeholders to ensure that each project meets specific requirements and expectations. Their commitment to safety and sustainability is evident in their construction practices, which prioritize minimizing environmental impact while maximizing efficiency.

Tensar International Corporation specializes in geosynthetic solutions for civil engineering projects, including bridge construction. Their innovative products enhance the performance and longevity of steel bridges. By integrating geosynthetic materials into bridge designs, Tensar helps improve load distribution and reduce settlement, which is crucial for maintaining the structural integrity of bridges over time.

Tensar's solutions are often integrated into steel box bridge designs, providing additional support and stability. Their focus on innovation helps improve the overall quality and efficiency of bridge construction. The company’s commitment to research and development ensures that they remain at the forefront of technological advancements in the industry, continually seeking ways to enhance the performance of their products and the structures they support.

Freyssinet is a global leader in the field of construction and engineering, known for its expertise in bridge design and construction. The company has a strong presence in the United States and offers a wide range of services. Their international experience allows them to bring best practices and innovative solutions to projects, ensuring high-quality outcomes.

Freyssinet specializes in advanced engineering solutions for steel bridges, including box girders. Their commitment to research and development ensures that they remain at the forefront of bridge technology. The company’s innovative approaches include the use of high-performance materials and cutting-edge construction techniques, which enhance the durability and efficiency of their bridges. Their focus on sustainability is also evident in their efforts to minimize waste and reduce the environmental impact of their projects.

Civils and Structures is a prominent engineering firm that focuses on civil infrastructure projects, including bridge construction. Their expertise in steel fabrication and design makes them a valuable player in the industry. The company’s commitment to quality and innovation has earned them a strong reputation among clients and stakeholders.

Civils and Structures has been involved in various projects that utilize steel box girders, showcasing their ability to deliver high-quality structures that meet stringent safety standards. Their engineering team works closely with clients to develop customized solutions that address specific project challenges, ensuring that each bridge is designed to perform optimally under varying conditions. Their focus on collaboration and communication throughout the project lifecycle enhances the overall success of their endeavors.

Nucor Corporation is one of the largest steel producers in the United States, known for its commitment to sustainability and innovation. The company has a diverse range of products, including steel for bridge construction. Nucor’s focus on recycling and energy efficiency has positioned them as a leader in the steel industry, contributing to a more sustainable future.

Nucor's steel products are widely used in the construction of steel box bridges. Their focus on quality and efficiency has made them a preferred supplier for many bridge projects across the country. The company’s advanced manufacturing processes ensure that their steel meets the highest standards for strength and durability, making it suitable for a wide range of applications. Additionally, Nucor’s commitment to customer service and support helps ensure that clients receive the best possible solutions for their bridge construction needs.

U.S. Bridge is a leading manufacturer of prefabricated steel bridges, known for its innovative designs and efficient construction methods. The company has been in operation since 1936 and has a strong reputation in the industry. Their extensive experience allows them to offer a wide range of customizable bridge solutions that meet the diverse needs of their clients.

U.S. Bridge specializes in the design and manufacture of steel box bridges, offering a wide range of customizable options to meet the needs of various projects. Their commitment to quality and customer satisfaction sets them apart in the market. The company’s prefabricated bridge solutions allow for quick installation and reduced construction time, making them an attractive option for many infrastructure projects. Their focus on innovation and continuous improvement ensures that they remain competitive in the ever-evolving bridge manufacturing landscape.

The steel box bridge manufacturing industry in America is characterized by a diverse range of companies, each contributing to the development of infrastructure in unique ways. From the innovative designs of EVERCROSS BRIDGE to the historical significance of American Bridge Company, these manufacturers play a crucial role in shaping the future of transportation. As infrastructure needs continue to grow, the importance of these manufacturers will only increase, driving advancements in technology and construction practices. The ongoing collaboration between these companies and their commitment to quality and innovation will ensure that steel box bridges remain a reliable and efficient solution for transportation needs in the years to come.

The dimensions of steel box girder bridges can vary significantly based on the specific design and application. Typically, the width of the box girders ranges from 1 to 3 meters, while the height can be between 0.5 to 2 meters. The weight limitations depend on the materials used and the design specifications, but they can support loads ranging from a few tons for pedestrian bridges to several hundred tons for heavy vehicular traffic.

Steel box girder bridges generally have a higher initial construction cost compared to concrete bridges due to the price of steel and the complexity of fabrication. However, they often have a longer lifespan, typically exceeding 50 years with proper maintenance, compared to concrete bridges, which may require more frequent repairs and have a lifespan of around 30 to 50 years. Additionally, steel bridges can be lighter, allowing for longer spans without the need for additional supports.

Recent advancements in steel box girder bridge design include the use of high-strength steel alloys, which reduce weight while increasing load capacity. Additionally, innovations in computer-aided design (CAD) and building information modeling (BIM) have improved the accuracy and efficiency of bridge design. Construction techniques have also evolved, with the adoption of modular construction methods that allow for faster assembly and reduced on-site construction time.

Regular maintenance practices for steel box bridges include inspections for corrosion, structural integrity assessments, and routine cleaning to remove debris and contaminants. Protective coatings are often applied to prevent rust and deterioration. Additionally, monitoring systems can be installed to track the bridge's health over time, allowing for timely repairs and maintenance interventions.

The choice between steel and concrete for bridge construction is influenced by several factors, including the intended use of the bridge, environmental conditions, budget constraints, and design requirements. Steel is often preferred for longer spans and heavier loads due to its strength-to-weight ratio, while concrete may be chosen for its durability and lower initial cost in certain applications. Additionally, local availability of materials and construction expertise can also play a significant role in the decision-making process.