Views: 211 Author: Site Editor Publish Time: 2025-12-19 Origin: Site

Content Menu

● EVERCROSS BRIDGE: A Leader in Steel Box Bridge Manufacturing

● The Importance of Steel Box Bridges

>> Advantages of Steel Box Bridges

● Other Notable Steel Box Bridge Manufacturers in Saudi Arabia

>> 1. Saudi Arabian Amiantit Company

● The Future of Steel Box Bridge Manufacturing in Saudi Arabia

>> Innovations in Steel Bridge Technology

>> Collaboration and Partnerships

● Frequently Asked and Questions regarding Steel Box Bridge Manufacturers

>> 1. How do Saudi Arabian steel box bridge manufacturers ensure quality control and safety?

>> 2. What are some innovative design trends in steel box bridge construction globally?

>> 3. How does the Vision 2030 initiative impact steel box bridge projects in Saudi Arabia?

>> 4. What role do public-private partnerships play in steel box bridge construction in Saudi Arabia?

Steel box bridges are essential structures in modern infrastructure, providing robust solutions for transportation networks. In Saudi Arabia, the demand for such bridges has surged due to rapid urbanization and the need for improved connectivity. This article explores the top steel box bridge manufacturers in Saudi Arabia, highlighting their contributions to the industry and showcasing their capabilities.

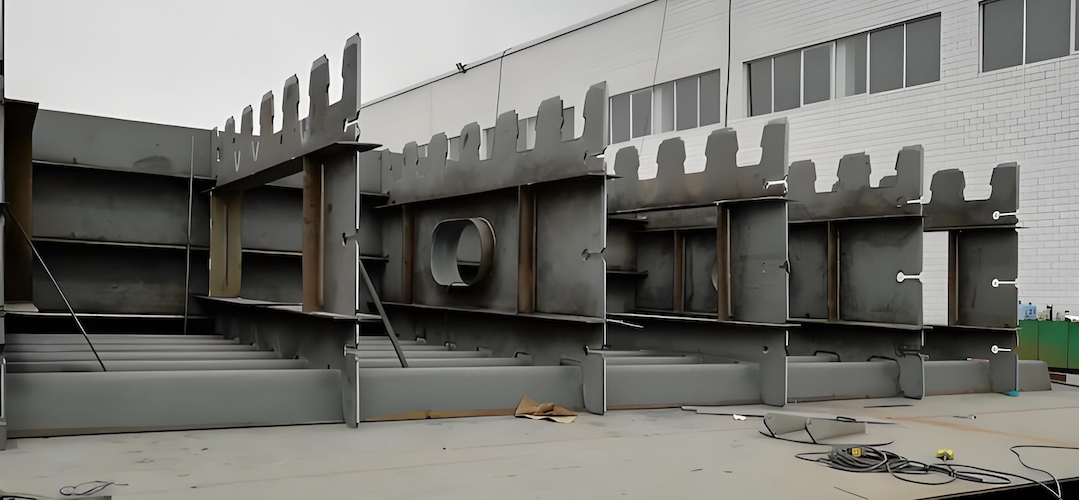

EVERCROSS BRIDGE stands out as one of the top manufacturers of steel box bridges in China, with an impressive annual production capacity exceeding 10,000 tons. The company has established itself as a reliable partner for major projects, collaborating with prominent enterprises such as China Communications Construction Company, China Railway Group, China Electric Power Construction Group, Gezhouba Group, and China National Offshore Oil Corporation. These partnerships have enabled EVERCROSS BRIDGE to participate in significant railway, highway, and international government procurement projects.

The company’s commitment to quality and innovation has positioned it as a leader in the steel bridge manufacturing sector. With a focus on advanced technology and sustainable practices, EVERCROSS BRIDGE continues to expand its influence in the global market, including potential ventures in Saudi Arabia. Their state-of-the-art manufacturing facilities utilize cutting-edge technology to ensure precision and efficiency in production, which is crucial for meeting the stringent demands of large-scale infrastructure projects. Furthermore, EVERCROSS BRIDGE emphasizes research and development, continually seeking to improve their products and adapt to the latest industry trends.

Steel box bridges are favored for their strength, durability, and versatility. They are designed to withstand heavy loads and harsh environmental conditions, making them ideal for various applications, including highways, railways, and pedestrian walkways. The use of steel box bridges can significantly reduce construction time and costs, providing an efficient solution for infrastructure development.

Steel box bridges offer several advantages over traditional bridge designs. Their lightweight structure allows for easier transportation and installation, while their robust design ensures longevity and minimal maintenance. Additionally, steel box bridges can be prefabricated, allowing for quicker assembly on-site, which is particularly beneficial in urban areas where time and space are limited. The ability to prefabricate components off-site not only accelerates the construction process but also enhances safety by reducing on-site labor requirements. This efficiency is especially important in densely populated regions where construction disruptions can impact local communities.

Moreover, the aesthetic flexibility of steel box bridges allows for innovative designs that can enhance the visual appeal of infrastructure projects. Architects and engineers can collaborate to create structures that not only serve functional purposes but also contribute to the overall landscape and urban design. This aspect is increasingly important as cities strive to integrate infrastructure with environmental and aesthetic considerations.

While EVERCROSS BRIDGE leads the way, several other manufacturers in Saudi Arabia contribute to the steel box bridge market. These companies are recognized for their expertise, quality, and innovative solutions.

Saudi Arabian Amiantit Company is a prominent player in the construction and manufacturing sector. Known for its diverse range of products, the company has made significant strides in the production of steel structures, including box bridges. Amiantit’s commitment to quality and sustainability has earned it a strong reputation in the industry. The company employs advanced manufacturing techniques and adheres to international standards, ensuring that its products meet the rigorous demands of modern infrastructure projects.

Amiantit also invests in research and development to enhance the performance and durability of its steel structures. By focusing on innovative materials and construction methods, the company aims to provide solutions that not only meet current needs but also anticipate future challenges in infrastructure development.

Al-Babtain Group is another key manufacturer in Saudi Arabia, specializing in various steel structures. The company has extensive experience in the construction of bridges and has successfully completed numerous projects across the region. Al-Babtain Group’s focus on innovation and customer satisfaction has positioned it as a trusted partner in infrastructure development. Their engineering team is skilled in designing custom solutions that cater to specific project requirements, ensuring that each bridge is optimized for its intended use.

Additionally, Al-Babtain Group emphasizes sustainability in its operations, striving to minimize environmental impact through responsible sourcing of materials and efficient manufacturing processes. This commitment to sustainability resonates with the growing emphasis on eco-friendly construction practices in the region.

Al-Falak Construction is known for its expertise in civil engineering and construction. The company has a strong portfolio of projects, including the design and construction of steel box bridges. Al-Falak’s commitment to quality and safety ensures that its bridges meet the highest standards of performance and durability. The company employs a rigorous quality control process throughout the manufacturing and construction phases, which helps to mitigate risks and enhance the reliability of its structures.

Furthermore, Al-Falak Construction actively engages in community development initiatives, recognizing the importance of infrastructure in improving the quality of life for residents. By participating in local projects and supporting educational programs, the company demonstrates its commitment to social responsibility.

Al-Rashid Group is a well-established construction company in Saudi Arabia, with a diverse range of services, including bridge construction. The company has a reputation for delivering high-quality steel structures, including box bridges, that meet the specific needs of its clients. Al-Rashid Group’s experience and expertise make it a valuable player in the steel bridge manufacturing sector. Their project management approach emphasizes collaboration with clients and stakeholders, ensuring that projects are completed on time and within budget.

In addition to its technical capabilities, Al-Rashid Group is dedicated to fostering a culture of safety and excellence within its workforce. The company invests in training and development programs to equip its employees with the skills necessary to excel in their roles, thereby enhancing overall project outcomes.

As Saudi Arabia continues to invest in infrastructure development, the demand for steel box bridges is expected to grow. The government’s Vision 2030 initiative aims to enhance transportation networks and improve connectivity across the country. This presents significant opportunities for steel box bridge manufacturers to expand their operations and contribute to the nation’s development goals.

The future of steel box bridge manufacturing will likely be shaped by advancements in technology. Innovations such as modular construction, smart materials, and sustainable practices are expected to play a crucial role in the industry. Manufacturers that embrace these technologies will be better positioned to meet the evolving needs of the market. For instance, the integration of smart sensors into bridge designs can facilitate real-time monitoring of structural integrity, allowing for proactive maintenance and enhanced safety.

Moreover, the use of environmentally friendly materials and construction methods will become increasingly important as sustainability becomes a priority in infrastructure projects. Companies that prioritize green practices will not only comply with regulations but also appeal to environmentally conscious clients and stakeholders.

Collaboration between manufacturers, government agencies, and engineering firms will be essential for the successful implementation of steel box bridge projects. By working together, stakeholders can leverage their expertise and resources to deliver high-quality infrastructure solutions that meet the demands of modern transportation networks. Public-private partnerships can facilitate investment in large-scale projects, enabling faster execution and improved outcomes.

Additionally, knowledge sharing and collaboration on research initiatives can drive innovation in bridge design and construction techniques. As the industry evolves, fostering a culture of collaboration will be key to addressing challenges and seizing opportunities in the steel box bridge market.

The steel box bridge manufacturing industry in Saudi Arabia is poised for growth, driven by increasing infrastructure investments and the need for efficient transportation solutions. EVERCROSS BRIDGE, along with other notable manufacturers such as Saudi Arabian Amiantit Company, Al-Babtain Group, Al-Falak Construction, and Al-Rashid Group, plays a vital role in this sector. As the industry evolves, these companies will continue to innovate and adapt, ensuring that they meet the challenges of the future while contributing to the development of Saudi Arabia’s infrastructure. The ongoing commitment to quality, sustainability, and collaboration will be essential in shaping the future of steel box bridges in the region, ultimately enhancing the connectivity and quality of life for its residents.

Saudi Arabian manufacturers implement rigorous quality control measures throughout the production and construction processes. This includes adhering to international standards, conducting regular inspections, and utilizing advanced testing methods to assess material integrity. Safety protocols are also prioritized, with comprehensive training programs for workers and strict adherence to safety regulations to minimize risks during construction.

Globally, innovative design trends in steel box bridge construction include the use of modular construction techniques, which allow for prefabrication of bridge components off-site. This approach reduces construction time and enhances safety. Additionally, the integration of smart technologies, such as sensors for real-time monitoring of structural health, is becoming increasingly popular. Sustainable design practices, including the use of recycled materials and energy-efficient construction methods, are also gaining traction.

The Vision 2030 initiative aims to diversify the Saudi economy and improve infrastructure across the country. This has led to increased investments in transportation networks, including the construction of steel box bridges. As a result, manufacturers are experiencing heightened demand for their products, and new projects are being launched to enhance connectivity and support economic growth.

Public-private partnerships (PPPs) play a crucial role in financing and executing steel box bridge projects in Saudi Arabia. These collaborations allow for shared investment risks and resources, facilitating the development of large-scale infrastructure projects. By leveraging the expertise of private companies alongside public sector support, PPPs can enhance project efficiency, reduce costs, and ensure timely completion of essential infrastructure.