Views: 211 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Content Menu

● Understanding Modular Bridges

>> Advantages of Modular Bridges

● Innovative Materials in Modular Bridge Construction

>> Steel and Composite Materials

● Design Innovations in Modular Bridges

● Case Studies of Innovative Modular Bridges

● Future Trends in Modular Bridge Materials

>> Increased Use of Automation

>> Advancements in Material Science

>> Focus on Resilience and Sustainability

● Frequently Asked and Questions regarding Modular Bridge

>> 4. How does the use of smart materials enhance the functionality of modular bridges?

>> 5. What role does prefabrication play in the efficiency of modular bridge construction?

The evolution of bridge construction has seen a significant shift towards modular designs, which offer numerous advantages in terms of efficiency, cost-effectiveness, and sustainability. As the demand for infrastructure grows, so does the need for innovative materials that can enhance the performance and longevity of these structures. This article explores the innovative materials being used in modern modular bridge designs, highlighting their benefits and applications.

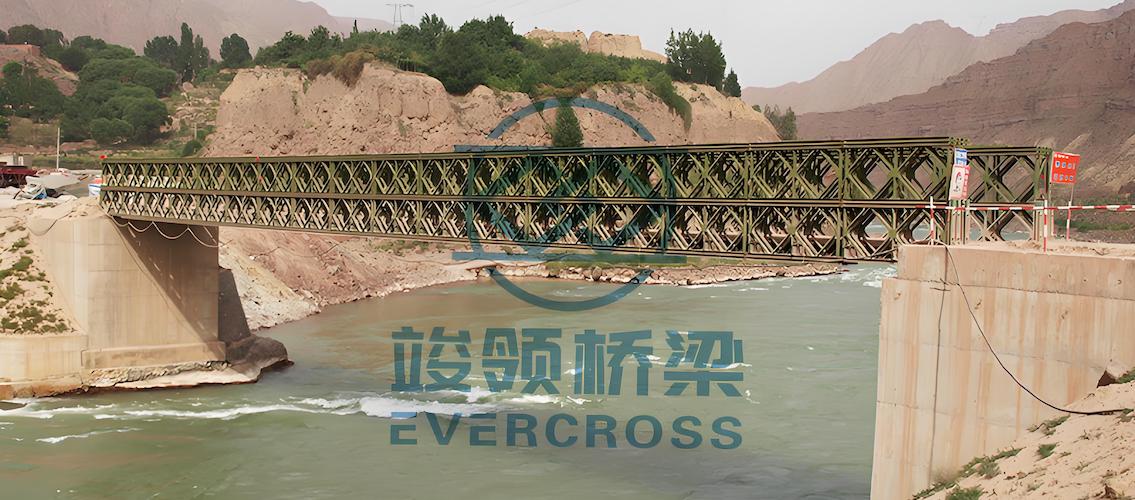

A modular bridge is a structure that is prefabricated in sections or modules, which are then transported to the construction site for assembly. This approach allows for quicker installation and reduced disruption to the surrounding environment. Modular bridges can be designed for various applications, including pedestrian walkways, vehicular traffic, and even railway crossings. The modularity of these bridges not only facilitates rapid deployment but also allows for easy customization to meet specific site conditions and user needs. This adaptability is particularly beneficial in urban settings where space and time constraints are prevalent.

Modular bridges offer several advantages over traditional bridge construction methods. They can be built off-site, which minimizes on-site construction time and reduces labor costs. Additionally, the modular approach allows for greater flexibility in design, enabling engineers to create customized solutions that meet specific site requirements. Furthermore, modular bridges can be easily relocated or expanded, making them an ideal choice for temporary or evolving infrastructure needs. The reduced construction time also means that traffic disruptions are minimized, which is a significant advantage in busy urban areas. Moreover, the ability to pre-fabricate components in a controlled environment enhances quality assurance, leading to more durable and reliable structures.

High-performance concrete (HPC) is a crucial material in modern modular bridge designs. This type of concrete is engineered to provide superior strength, durability, and resistance to environmental factors. HPC can withstand extreme weather conditions, making it suitable for bridges in harsh climates. Its enhanced properties also allow for thinner sections, reducing the overall weight of the bridge and facilitating easier transportation and installation. The use of HPC not only extends the lifespan of the bridge but also reduces the need for frequent repairs, which can be costly and time-consuming. Additionally, HPC can be formulated to include various additives that improve its workability and performance, further enhancing its suitability for modular applications.

Fiber-reinforced polymers (FRP) are increasingly being used in modular bridge construction due to their lightweight and high-strength characteristics. FRP materials, which include glass, carbon, or aramid fibers embedded in a polymer matrix, offer excellent resistance to corrosion and fatigue. This makes them particularly suitable for bridges exposed to harsh environmental conditions, such as saltwater or industrial pollutants. The use of FRP can significantly extend the lifespan of a bridge while reducing maintenance costs. Moreover, the lightweight nature of FRP allows for easier handling and installation, which can further reduce labor costs and construction time. As research continues, the development of new FRP formulations may lead to even greater performance enhancements, making them a staple in future modular bridge designs.

Steel remains a popular choice for modular bridge construction due to its high strength-to-weight ratio and versatility. However, the introduction of composite materials that combine steel with other materials, such as concrete or polymers, is gaining traction. These composite materials can enhance the structural performance of bridges while reducing their weight. For instance, hybrid systems that incorporate both steel and concrete can provide improved load-bearing capabilities and resistance to dynamic forces. The combination of materials also allows for innovative design possibilities, enabling engineers to optimize the structural efficiency of bridges. Furthermore, the use of composite materials can lead to reduced fabrication times and costs, making them an attractive option for modular construction.

Sustainability is a key consideration in modern bridge design. The use of recycled materials, such as reclaimed steel or recycled concrete aggregates, is becoming more common in modular bridge construction. These sustainable materials not only reduce the environmental impact of bridge building but also contribute to the circular economy by reusing existing resources. Additionally, the incorporation of green materials, such as bio-based composites, is being explored to further enhance the sustainability of modular bridges. The focus on sustainability extends beyond materials to include energy-efficient construction practices and the potential for bridges to incorporate renewable energy sources, such as solar panels, which can power lighting and other systems.

The prefabrication of bridge components is a significant innovation in modular bridge design. Advanced manufacturing techniques, such as 3D printing and automated fabrication, allow for precise and efficient production of bridge modules. This not only speeds up the construction process but also ensures high-quality standards. Prefabrication also enables the integration of complex designs and features, such as built-in lighting or drainage systems, directly into the modules. The ability to produce components in a factory setting also minimizes the impact of weather-related delays, ensuring that projects stay on schedule. As technology advances, the potential for even more sophisticated prefabrication methods will likely emerge, further enhancing the efficiency and effectiveness of modular bridge construction.

The integration of smart materials into modular bridge designs is an exciting development in the field of civil engineering. Smart materials can respond to environmental changes, such as temperature fluctuations or structural loads, by altering their properties. For example, shape memory alloys can return to their original shape after deformation, providing enhanced resilience to dynamic forces. The use of smart materials can improve the safety and performance of modular bridges, allowing for real-time monitoring and maintenance. This capability not only enhances the longevity of the structure but also provides valuable data that can inform future design and construction practices. As the Internet of Things (IoT) continues to expand, the potential for smart bridges equipped with sensors and communication systems will revolutionize how we approach infrastructure management.

The principles of modular design emphasize flexibility, scalability, and adaptability. By utilizing modular components, engineers can create bridges that can be easily modified or expanded to accommodate changing traffic patterns or environmental conditions. This adaptability is particularly important in urban areas where infrastructure needs may evolve over time. Modular design also allows for the rapid deployment of temporary bridges in emergency situations, providing critical access when needed most. The ability to quickly assemble and disassemble modular bridges also means that they can be relocated as necessary, making them a versatile solution for various applications. This flexibility not only meets immediate needs but also aligns with long-term urban planning goals.

The Solaire Bridge, located in a coastal region, showcases the use of high-performance concrete and fiber-reinforced polymers in its construction. Designed to withstand harsh marine conditions, the bridge features a modular design that allows for quick assembly and minimal disruption to the surrounding ecosystem. The use of sustainable materials in its construction further emphasizes the commitment to environmental stewardship. This bridge serves as a model for future projects, demonstrating how innovative materials can be effectively utilized to create resilient infrastructure that harmonizes with its environment. The Solaire Bridge not only meets functional requirements but also enhances the aesthetic appeal of the area, contributing to the overall quality of life for residents and visitors alike.

The Smart Bridge Project is an innovative initiative that incorporates smart materials and advanced monitoring systems into its modular design. This bridge features sensors embedded within the structure that continuously monitor its health and performance. The data collected can be used to predict maintenance needs and ensure the safety of users. This project exemplifies the future of modular bridge design, where technology and materials work together to create safer and more efficient infrastructure. By leveraging real-time data, engineers can make informed decisions about maintenance and upgrades, ultimately extending the lifespan of the bridge and enhancing public safety. The Smart Bridge Project represents a significant step forward in the integration of technology into civil engineering, paving the way for smarter, more responsive infrastructure.

As technology continues to advance, the use of automation in the production of modular bridge components is expected to increase. Automated systems can enhance precision and efficiency, reducing the time and cost associated with bridge construction. This trend will likely lead to the development of more complex and innovative designs that were previously unattainable. Automation not only streamlines the manufacturing process but also reduces the potential for human error, resulting in higher quality components. As automation technologies evolve, they will enable the construction industry to meet the growing demand for infrastructure while maintaining high standards of safety and performance.

Ongoing research in material science is likely to yield new materials with enhanced properties for modular bridge construction. Innovations such as self-healing concrete, which can repair its own cracks, and ultra-lightweight composites are on the horizon. These advancements will further improve the performance and sustainability of modular bridges, making them an even more attractive option for infrastructure development. The exploration of nanomaterials and bio-inspired designs may also lead to breakthroughs that enhance the strength and durability of bridge components. As these new materials become available, they will provide engineers with a broader toolkit for addressing the challenges of modern infrastructure.

The future of modular bridge design will increasingly prioritize resilience and sustainability. As climate change poses new challenges to infrastructure, the development of materials that can withstand extreme weather events will be crucial. Additionally, the emphasis on sustainable practices will drive the use of recycled and eco-friendly materials in bridge construction, aligning with global efforts to reduce carbon footprints. The integration of renewable energy sources into bridge designs, such as solar panels or wind turbines, will also become more common, allowing bridges to contribute to energy generation. This holistic approach to design will ensure that modular bridges not only serve their immediate purpose but also contribute positively to the environment and society as a whole.

The integration of innovative materials in modern modular bridge designs is transforming the landscape of infrastructure development. High-performance concrete, fiber-reinforced polymers, and sustainable materials are just a few examples of how advancements in material science are enhancing the performance and longevity of bridges. As technology continues to evolve, the future of modular bridge construction looks promising, with increased automation, smart materials, and a focus on resilience and sustainability paving the way for more efficient and environmentally friendly infrastructure solutions. The ongoing exploration of these materials and design principles will undoubtedly lead to safer, more adaptable, and sustainable bridges for generations to come. The commitment to innovation in this field not only addresses current infrastructure challenges but also sets the stage for a more sustainable and resilient future.

Long-term maintenance costs for modular bridges can be significantly lower than traditional bridges, especially when using innovative materials like fiber-reinforced polymers and high-performance concrete. These materials are designed to resist corrosion and fatigue, reducing the frequency and cost of repairs. However, specific costs can vary based on environmental conditions, usage, and the materials used.

Innovative materials such as recycled steel and high-performance concrete generally have a lower environmental impact compared to traditional materials. Lifecycle assessments show that these materials can reduce carbon emissions during production and throughout their lifespan. Additionally, materials like fiber-reinforced polymers offer durability that extends the lifecycle of the bridge, further minimizing environmental impact.

The primary challenges include the high initial costs of research and development, the need for standardized testing and certification processes, and the potential lack of familiarity among engineers and construction workers with new materials. Additionally, regulatory hurdles and the need for public acceptance can slow the adoption of innovative materials in modular bridge construction.

Smart materials can adapt to environmental changes, providing real-time data on structural health and performance. For example, materials that change properties in response to temperature or load can help prevent structural failures. This capability allows for proactive maintenance and enhances the overall safety and longevity of modular bridges.

Prefabrication allows for the construction of bridge components in a controlled environment, which improves quality and reduces construction time on-site. This method minimizes disruptions to traffic and the surrounding area, leading to faster project completion. Additionally, prefabrication can lead to cost savings by reducing labor and material waste during the construction process.